THE EH-1000

After years of use and then storage once the analog Teletext television system was turned off yonks ago, I have finally gotten around to placing this professional, very well built equipment onto the workshop bench ... the "operation" has begun

This equipment was fully functioning but of no possible further use in our digital television (with no teletext broadcasts) era so now I have extracted components and modules "of interest" which can be used to restore another EH-1000 or think of this board as a "component farm" a place where some difficult (or impossible) spare parts may lurk ...

This component is the AC input transformer, secondary voltages are connected to the PSU Board via flying leads and connectors - ALMOST unsoldering-soldering to undertake, see my notes below.

One of the first things to note about the Unaohm EH-1000 is that although it had an ID label on the rear identifying it as Made in Italy (Milano), most of the passive and active components are from Europe. Unfortunately though, SOME components have minimal or no identification at all.

This AC transformer falls into the category of having minimal labelling - a paper label on the top of the laminations and that's it.

Don't have an EH-1000? (and who has these days!) - all is not lost because I can think of many other uses for this transformer (taking note of the design voltage for primary windings) One alternative is for use with a nice little valve based preamp or perhaps even a low power output stage as well. The higher voltage winding is ready and waiting, as is the heater supply. Read further down in this lengthy description to learn more about this transformer ...

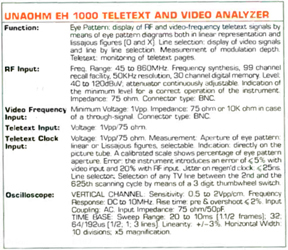

If you have never heard of the EH-1000, here is some basic information ...

THE DONOR EQUIPMENT

UNAOHM - Teletext Video RF Analyser

Model: EH-1000

Designed & manufactured in Milano, ITALY

Circa Late 1980's (based on advertisements placed in Wireless World at the time and the apparent date stamp on the AC transformer core)

Technology: Analog video broadcast signal analysis - specifically for examining lines of Teletext information "riding along" with the video signal

Luggable (heavy at 15kg) due to the heavy duty Aluminium outer case but more importantly, the inside welded steel frame chassis inside.

Well engineered inside, logically laid out using a number of modules which are well interconnected.

Designed for 220V 50Hz operation (because of this, we used this equipment via an AC variac many years ago)

Green emitting rectangular CRT based front panel display

Interested in the technical nitty gritty? Here is an old copy of the spec sheet

Now let's get down to the nitty gritty of what this transformer is all about

AC POWER TRANSFORMER

Country of origin cannot be established - not indicated (it certainly will not be Asian though!)

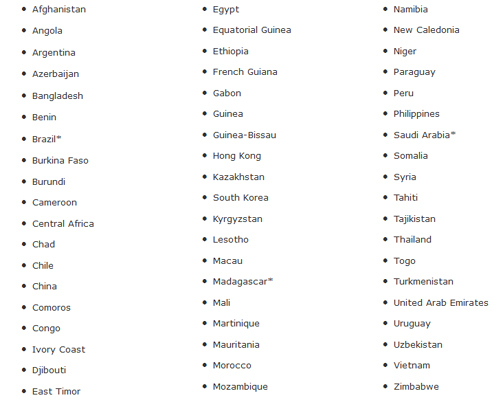

Most likely European manufacture but the target market is uncertain - 110V on the primary is understandable for USA power systems but where was the target market for 220V?

Well it seems that quite a few countries use 220V ...

Part number identification (the ONLY identification on the transformer)

20 05 88 (I would assume this is the manufacture date-year)

5486

That's it folks! No other information or markings at all

Iron E core

lacquered laminations

Primary connections are solder tags

One secondary winding is also solder tags

The remaining secondary windings are actually solder tags but "buried" in some sort of silicon based gunk which doesn't look terribly difficult to remove if the need is there. From these solder tags are flying leads with female plugs designed to mate with the PSU board connectors.

ALL WINDINGS ARE ELECTRICALLY ISOLATED FROM EACH OTHER - THIS IS NOT AN AUTO TRANSFORMER!

PRIMARY:

Two windings, currently wired in series. Each winding has the same DC resistance so there is a pretty good chance that if the strap between the windings was cut, this could be used with a 110V AC input supply.

I have left the strap in place (for 220V operation) and a pigtail lead which was the AC input lead originally (Black)

Not designed for 240V AC operation - you may wish to try (at your own risk) as the Austraiian "standard" AC input is just 10% higher approximately (it can be anywhere between 240 ~ 250V depending upon the system load), with resulting 10%+ increases in the secondary voltages but downgrading the current drawn from each winding and overall would be a sensible idea.

I do not have ANY technical specifications for this transformer but based purely on the physical size of the core and it's past use, I feel that around 100VA maximum for ALL secondary windings in total would be pretty safe.

SECONDARIES:

Solder tags next to the primary connections 6.5V (Heater supply)

Blue-Blue 115V

Yellow-Yellow 36V

Red-Red 41V

Grey-Grey 10.6V

Black (Closest to Red) N/C 130pF capacitance measured to Ground (frame)

Black (Closest to Grey) N/C 85pF capacitance measured to Ground (frame)

The Blue-Blue output grabbed my attention (valves! I thought) although a little low perhaps as most tube anodes like between 250 ~ 300V but perhaps a candidate for a voltage doubling rectifier on the output or even connecting one or more of the other secondaries to create a larger AC source voltage to start with. Sounds like an experimentation exercise here for someone!

Interesting is the TWO Black wires which go to the connectors. They are not associated electrically with ANY winding nor are they connected to the frame of the transformer.

Each Black wire is isolated from the other.

The only possible reason for these wires that I can think of is that they are intended to reduce Common Mode Noise as it is not often you find AC transformers with TWO "Faraday" shields. Externally I cannot see any Copper banding at all, the windings have a dark Brown insulation of some sort covering them.

DIMENSIONS:

Core: 84mm wide x 45mm deep x 72mm height

4x metal mounting feet form part of the frame and if these are included in the measurements, the size is 84mm wide x 80mm deep x 72mm height

WEIGHT:

2Kg

It is a shame that the manufacturer decided not to completely identify who they are, this is a well made transformer and it would have been good to know the manufacturer!

This transformer is now resting on a stiff base and well protected in a cocoon of bubblewrap while it awaits a new purpose in life.