WORKING special purpose test equipment or cannabilise for the excellent parts (described below)

First photograph is in the "power on" condition, just over 1KV output

Sanki High Frequency Noise Simulator

Model: ENS-24XA

Designed in Japan

This test equipment is designed to generate "high frequency noise" to test the resilience of the equipment under test to line borne noise, particularly digital equipment.

High-speed pulses can be superimposed on the power supply line and this equipment is widely used as a standard for noise testing.

You set the voltage output, the pulse width and repetition rate - all controls for these functions are to the right hand side of the front panel and via the maze of BNC patch cables to user sets up.

The front panel left hand side is the injection point onto the line supply for the pulse characteristics chosen by the user - there is a separate supply line (input and output) for the equipment under test.

BASIC SPECIFICATIONS:

Pulse width: 50ns to 1000ns Manually selected with patch cables

Output impulse voltage 0 to 2000V DC

Impedance of generator 50Ω

Pulse polarity is switch selectable: Positive or Negative

Rise time 0.7 to 1ns (50Ω)

Operation modes

Manual - single shot

External trig with TTL signal

Internal clock 20 to 80Hz (front panel adjustable)

Phase angle of the pulses: 0° to 360° (front panel adjustable)

Designed to run off 200 - 240V AC (Set it for 240V operation)

Dimensions: 400mm × 430mm × 250mm

Weight: 20Kg

COSMETIC CONDITION:

Very good to excellent - no structural case damage just a couple of scratches here and there and a knob centre cap missing.

TESTING:

Visual inspection, no signs of component stress

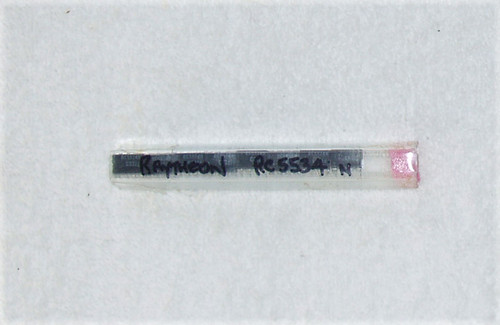

Components of interest:

AC transformer TOYOZUMI 200VA Primaries 200-220-240 and Secondaries 100 - 115

A small plug in printed circuit board has 100V AC supply in and provides 5V and 12V from two SMP blocks - voltages checked and are correct.

Large vertical mounted board is the DC high voltage supply - the voltage is indicated on the front panel meter, you can also access this voltage at a front panel BNC connector.

Voltages indicated have been confirmed with my multi-meter and I can wind it up to 2KV with no effort.

Trigger circuits are working, on external trigger and internal slow oscillator I can hear the relay (reed?) operating at the rear (inserted in-line with the pulse output coax)

Very nicely engineered in-line switch at the rear (see the rear photograph)

Another transformer provides 115V AC and powers the variable DC supply for the output.

Front panel meter is working fine, zero rest & no sticking etc.

Medium sized rheostat (used to control the output pulse voltage) looks to be in excellent condition.

Matsuanga Type PH-131 100V AC input and 0-130V output

This is the primary control of the DC Voltage output.

It has a side mounted microswitch which kicks the DC supply into operation once the rheostat is moved from fully counter-clockwise.

Two very large wirewound ceramic body resistors are 85K Nissei - series output, presumably to limit current.

Two very nice ERDE oil capacitors 1uF 4KV with large ceramic insulators

Nice easy to understand layout, DC high voltage supply is dominant with masses of coax cable underneath connected to the various pulse width BNC sockets. The shaped pulse is then applied via the switch at the rear, then the output pulse(s) from this switch are then superimposed on the line supply for the equipment under test (input is the 20A circular connector at the rear and the output is available.

Think of the front panel as a patch bay, you can determine the pulse width, patch it to the switch and then patch it to either side (or both) of the supply line.

No strange noises, No funny smells at turn on or during operation!

Look around online to see current asking prices and even though quite old equipment, the typical asking price is anywhere between US$1000 and US$3000 UNTESTED!