HISTORY:

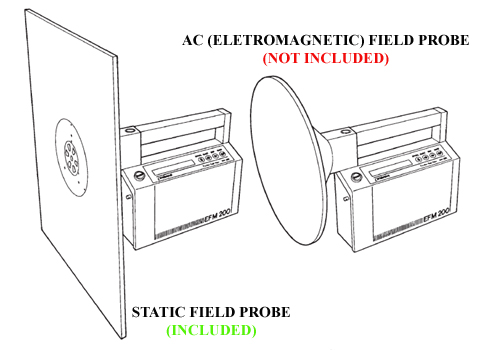

This is called an Electric Field Meter incorporating a precision field mill for the accurate measurement of electrical charge (static) and originally used in an international CRT (remember them?) manufacturing facility. Obsoleted equipment once the death knells of CRT technology became obvious. But this instrument (and it is a true instrument not a little handheld "toy") is also capable of accurately measuring AC or Electromagnetic fields BUT an additional probe is required (NOT SUPPLIED)

I imported this equipment into Australia (along with a large amount of "other" interesting test & measurement equipment quite some time back) ... once received, I have ignored this equipment and it has been sitting in my storage units waiting for me to have a good hard think about who may find this interesting.

Last week I was prompted to bring this out of the storage and take a good close look at it, see what it can do and test to see if it actually works!

The field mill in particular is interesting but the overall concept was of interest too so if you are like me and wish to do some "homework" on the theory of operation and just who uses these , it may interest you to take a look HERE or HERE as starting points but there are truly volumes of very "detailed" information about the principles involved and current useage.

What on earth would you want one for (you may well ask, with a confused look and one eye closed)?

This is a very sensitive instrument which allows for the detection and measurement of both electro-static fields and a guide to the amount of charge AND electro-magnetic fields, particularly at extremely low (5hz ~ 2Khz) or very low frequencies (2Khz ~ 400Khz) when the electromagnetic probe is fitted (not supplied)

The plate required for electrostatic field measurement IS INCLUDED

The probe required for electromagnetic field measurement IS NOT INCLUDED (Shame!)

I admit that up until recently I knew very little about the capabilities of this equipment, not ever needing to measure such fields but as I have learned more about these devices it seems that the use of a Electric Field Meter could be VERY interesting - it's a bit like getting a "window" into an invisible world, the world of electro-static and electro-magnetic fields.

I have read articles about folks using such instruments for near field measurement work, some experimenting with detecting and measuring extremely high levels of electro-static charges (lightning) or with the electromagnetic probe fitted, a scientist associate told me that earthquakes generate EMF at extremely low frequencies, well before the seismic waves are felt by humans when there is a rupturing and there are even some people who have experimented with detecting and measuring human electro-magnetic fields or waves from the brain using a helmet arrangement!

Certainly a very interesting piece of gear with some exciting potential but it's not for me ... I have WAY too much equipment already and this area of research is not "my cuppa o' tea" so I am hoping that someone else will see the potential of this equipment and make it do some useful work once more.

Don't let the LARGE plywood carry case (almost a full suit case size) scare you off, I will ship this anywhere and it is not too heavy (15Kg packed) but it is quite large (see below for details). The size is due mainly to the large electrostatic sensor plate included in the box.

ELECTRIC FIELD METERS:

I am offering this equipment for R&D or for ES or EM Field curiosity sake. My description of the instrument below is EXTREMELY detailed (otherwise how would you know if it will suit your purposes?) so if you have a genuine interest, please persist!

I have powered up the equipment and checked the functionality, full details of my tests and "playing around" are described below ...

COMBINOVA AB (SWEDEN) - Electric Field Meter

Designed and manufactured in Sweden

Circa 1990's

Model: EFM-200

Serial # 193

EQUIPMENT SUPPLIED:

Original carry case

Main Instrument (EFM200) with field mill (protected by a custom made clear plastic cover)

Square Electrostatic plate assembly

2x RS232 Interconnect cables with the special Gold plated 5x pin (circular pattern) sub-miniature plugs fitted

Multi-voltage AC charger (100 ~ 240V input) switchmode and most importantly with the special 2 pin Gold plated sub miniature plug to fit the EFM 200 external port.

NOTE: This AC charger is also switch selectable for various DC outputs 9V to 24V @ 30W (currently set to 12V) BUT the plug-pack does have the 2x round pins (no earth) as used in Asian countries so I will be supplying a "modified" adapter plug to suit Australian 240V GPO's. How modified? (I hear you ask enquiringly with your head lowered on one side) - well, it's that old trick, not really a great idea either, bent the pins to an angle!

Printed Operators Manual, 64 pages

NOT SUPPLIED:

NO Round Electromagnetic sensor for ELF or VLF (Extremely low frequency electromagnetic waves 5Hz to 4Khz) - if you are lucky, you may be able to find one of these online "somewhere"!

NO factory cover for the field mill. The previous R&D facility did not pack this into the case but instead supplied a simple clear plastic custom made cover to protect that very special central area (the rotatable Gold disc) - it is important to NEVER touch this area with your hands (oil/grease) otherwise the measurements will not be accurate.

NO grounding lead - this is nothing special, a length of single core wire with banana plugs at each end - this provides a reference to the field mill.

NO tripod, originally Combinova supplied this as a complete kit, including a tripod. You will need to provide your own (threaded hole in the base of the EFM 200 is used for mounting onto the tripod.

NO Lead Acid battery for portable/field use - the old battery was discarded and I saw no point in purchasing a new battery, yes you can still buy these if you hunt around or better still perhaps adapt the use to Li-Ion batteries but the charging circuit would need to be customised as well.

NO distance measuring tool, also originally supplied by Combinova but long since gone missing. Just use a contemporary equivalent, we call them rulers!

NO carbon fibre brush with single wire grounding lead is supplied - missing. Not the end of the world and the user/experimenter can make their own custom solution to this accessory.

NO calibration probe, I read about these "somewhere" but I don't have one in the case so if you wanted to make accurate measurements you will need to establish some sort of calibration setup yourself.

None of these non-included items above will affect the basic operation of the equipment, particularly for static field measurement. Of course if one was to start measuring ELF or VLF Electromagnetic fields then you will definitely need the round probe.

Although the very strong carry case is large/bulky, this is actually designed for "field use", you do not need to have it set up as a permanent installation.

The main instrument can be powered using the supplied AC adapter OR installed (not supplied though) Lead-Acid rechargeable battery.

COSMETIC CONDITION:

CARRY CASE:

CLEAN

Very good condition.

Construction is all plywood with top side Aluminium angle for all edges and what appears to be Zinc/Tin angle for the sides and base. A carry handle is mounted on the lid and the heavily hinged lid uses two heavy duty toggle clasps to kept everything safe inside while being transported.

NO damage at all to the plywood or the metal side angle material - no holes! not even any markings and no writing or labelling anywhere except the Blue manufacturers name on the lid.

This is what I would describe as "luggable" meaning it CAN be hand carried although cumbersome!

Carrying weight: 12Kg

Dimensions: 600mm width x 300mm deep x 550mm height

Keep in mind that although bulky, this should not "scare off" Australian persons who are interested because this will be offered with FREE shipping anywhere WITHIN AUSTRALIA. Of course I can send this internationally but it will not have free shipping included.

INSIDE THE CARRY CASE:

CLEAN

Very nice padding all round, separate compartments for the EFM 200, the large square plate and the accessories. Two compartments in the case are empty, probably intended for the round electromagnetic probe.

EFM 200 MAIN UNIT:

Yes, it looks like a large torch! I had to chuckle because my wife thought I was checking out a torch ...

Not at all heavy, weighing just 2.4Kg (remember this normally sits on top of a tripod) although this weight does NOT include the Lead Acid battery, which are normally quite heavy themselves.

NO damage to the case at all - in fact not even scratches or marks!

LCD display is not scratched or damaged and all touch buttons feel fine.

NO damage to any panel labels

Field mill at the front looks very clean and undamaged. This is a critical part of the instrument and it MUST be kept clean and NEVER touched, to avoid contamination.

Inside the EFM 200 it is very "original" looking, no-one has been servicing this equipment in the past - although I can only easily see the "top board"

Component details ... it's nice to know!

The EPROM is programmed with software version 1.01

***NOTE***

I am pretty sure this is one of the earliest production models from COMBINOVA, why? The serial # is just 193 and the software version is 1.01 - looking at the manual, it refers to software version 3.03 so there must have been upgrades since 1.01 was released. I have no idea what those updates "fixed" or improved, if anything.

Nice MAX666CPA for voltage regulation, SRM20256 CMOS 256K SRAM, a couple of the 68HC series processors and a smattering of 74HC logic chips. I then removed 4x screws (that's all) to reveal the underneath board, there are 3 PCB's in this unit, with the 3rd board being for the front panel LCD and control logic. On this PCB which sits underneath the "top board" there is an Analog Devices AD7572 complete 12 bit AD converter (socketed), Analog Devices AD637 complete rms to dc converter (socketed), a number of LM636 high speed Op amps, a number of DG441 high speed analog switches plus many other devices.

If ever the need should arise, this unit is a snap to "work on" with easy removal of the boards, looks to be double-sided PCB and NO SMD with the use of PCB connectors for external connections to the field mill, ports etc.

The one thing I could not easily find was the memory backup battery, there must be one somewhere but I couldn't readily see it. There is a "largish" Black cased component on the top board but it doesn't seem to be a battery, designated on the board as IC40 and underneath it has at least 5 connections - no battery there. While the equipment will still work fine, that battery (wherever it is) will need changing after 30 years otherwise the unit will "forget" measurements each time it is powered down - see my notes under TESTING about this aspect of the equipment.

SQUARE ELECTRO-STATIC PLATE:

This LARGE plate (500mm x 500mm) is in good condition. One side is Matt Black (facing the EFM 200) and it has 3x locating/locking pins - no damage or missing parts. The Black surface is unmarked. The "front side" is Silver in colour, looks like a metal such as Aluminium. This does have some surface marks (NOT scratches) but I have left it alone and not attempted to clean that side, not even sure if it is important to be "squeeky clean"

AC POWER PACK

CLEAN

Un-damaged EXCEPT someone has made a join in the DC output lead, in fact I believe that once in the life of this plug-pack it was with other equipment and re-wired (reversed the polarity) to suit the EFM 200 because it just doesn't "look like" original equipment from Sweden.

Well made joins, heatshrink insulation.

AUXILIARY COMMUNICATION CABLES (2)

Both are in very good condition, particularly the special sub miniature plugs. Both leads are terminated in D25 connectors, one female and the other male (Printer and RS232 comms)

TESTING:

This is the part the REALLY matters, and I find this task to be pretty exciting (just what can you do with this? that sort of thing)

Test setup: Due to no lead acid battery installed, I used a different 12V DC power source and "pretended" this was the lead acid battery (easy access to the battery spade connectors was my main reason)

I have checked the supplied power pack though, output (set to 12V) is 11.7V - I also checked that the DC polarity is correct! I am sure the previous user knew what they were doing but it's best to check anyway - I checked at the board and the correct polarity DC is present from the power pack. I have NOT tested the charging circuit for the non-existant Lead Acid battery, little point really ...

Pushed the Power ON/OFF button (left hand side) - LCD display comes alive (Blue/Green backlight) and a soft beep from the board piezo sounder.

Displays

ELECTRIC FIELD METER 200

91.04.04 12:40:27* (this is a clock and is incrementing in one second steps) 0

Showing it's age! The second line, first grouping is the year/month/day ... 1991

The display is fine, although much better when the nice Blue/Green backlight is ON - I was testing outside and I found the LCD very difficult to read in daylight UNLESS the backlight was on. I have not taken photographs of the LCD screen "in action" because quite simply my camera is dodgy at best, you just have to take my word for it - it DOES display everything I am stating below! NO deadspots, NO horrible "black" areas which indicative of physical damage - just a nice clean screen.

At this point the manual is very handy as it contains nice clear flow charts of the control functions (and there are many to choose)

I first went through the CHECK menu, no problems at all with any menu navigation or test results

Next was the PARAMETERS menu. This is where you can setup the real year/month & day, type of logs, sample rate, backlight timing 1,2,5,10,20 or 30 seconds, baud rate 300, 1200,2400 or 4800 for RS232 comms,print page size, OFF delay 1,2,5 or 10 minutes (no action and the unit powers down) and even the display language (American (!), English and Svenska (Swedish)

I also changed the clock settings, both to see if I can move things into the 21st century, the clock format and the ability to save those settings when powered down. The clock is important if data logging is being used, otherwise you would have no idea when different readings were being made!

All options changed as they should have (while power was on) and the clock was changed to 2023, July and the 10th day. NO year 2000 issues and the format is year/month/day

I then fitted the square plate (Electrostatic) to the front of the EFM 200 and went into the measurement menu section, selecting a single reading. This equipment will automatically make repeated readings and log all of the data but I didn't worry about testing that section. Other sections that I have NOT tested are the RS232 comms nor the printer functions.

Then pushed the GREEN button on top of the handle (START) and the Field Mill (Gold segmented disc) rotates (very fast) and very quietly too!

I hear you ... the central Gold disc ROTATES? Only the centre Gold section of the front rotates. This is the field mill which comprises a rotor (the front moving section) and a stator which does not move and the instrument uses an optical sensor to control the rotational speed and as a control input to the phase locked signal amplifiers. This instrument has 4 different automatic gain ranges (factory calibrated) to achieve high accuracy.

Of course I have not setup the calibration of the equipment at all although the manual does go into great detail about how to do this, I just wanted to see if I appeared to be measuring "something"

I had an "ambient" reading of 0.120Kv/m at this point showing on the LCD. Next I vigorously rubbed some plastic material to create a high static electric charge and bought it near the square probe .... Wow! it responded immediately with the readings going very high (compared to the ambient reading) in the range of 200 ~ 400Kv/m, depending upon how far away I was from the Field mill.

The equipment is certainly reading static electric fields, such a cool device!

Next, I powered OFF the EFM 200 (using the push button) and waited for 10 minutes, my purpose was to see if the changes I had made in the parameters had been "remembered" in memory.

One hour later and turned the EFM 200 back on, all settings retained. Now I will kill all power to the instrument, not just turn off the power at the front panel, to make sure there is no separate DC path being used for the memory backup.

Ok, so after another hour WITHOUT any power source attached to the instrument, all settings that I had made have been lost, the instrument has gone back in time to 1991! Definitely, if the need is to keep the settings, that internal battery must be found and changed otherwise the memory is going to always "forget" what you have told it unless you permanently connect a power source to the instrument.