HISTORY:

Sustainability is the name of the game! Anything (that has been tested and still functioning properly) should be repurposed creating saving in wasted Ee and reducing the poisoning our environment when items are buried in the earth at the local tip needlessly.

Never heard of Ee? It is a concept that creates a measurement of ALL things (not just electronics) that humans have made and the energy used in obtaining the raw material, processing the materials right through to a finished product and even should include the shipping of the item to the distributors/retailers.

If you would like to know more about Ee values, please take a look HERE

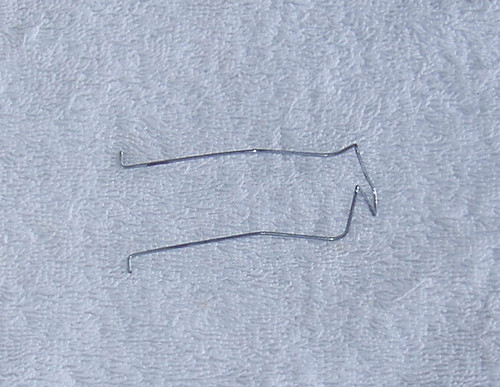

Hmmm, some more valve retaining springs that I found in my "box of tricks"

I have no idea which vintage equipment I retrieved these from, probably some more of the valve amplifiers that had become "organ donors" for other equipment. These retaining springs are of a slightly different design (and size) to the other "Hook Type" retainers I also have.

The top section of this retainer spring just sits at 90 degrees to the vertical, with a loop which fits over the pointed top of the valve glass envelope. Personally I liked the hook style retaining springs (advertised separately) more.

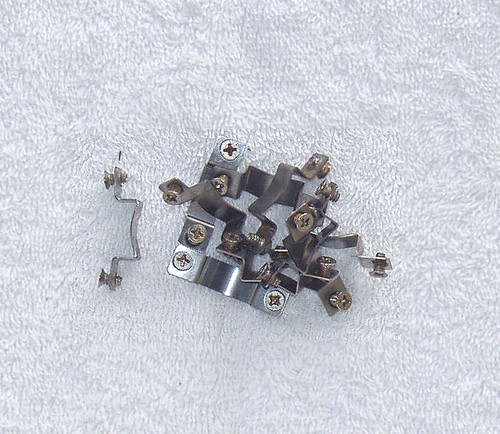

The idea with these is that as the equipment was moved around (as was often the case with film projection equipment), a means had to be used which ensured the valves stayed nice and snuggly in their sockets - this was the purpose of the retainer spring.

UNKNOWN MANUFACTURER - Valve Retainer Spring

As the equipment was manufactured just after WWII and it was common to either source components locally or make them yourself, I am pretty sure this retaining clip was Australian made, no idea by whom though.

Material: Spring Steel (confirmed ferrous)

I call this TYPE II (types are based on the spring height)

DIMENSIONS:

The spring steel is round and 0.8mm diameter

Base has two side outwards pointing hooks, this would fit into corresponding holes in the valve socket

34mm straight up until the "spring top hat" shaping begins

40mm height from the base "hooks" to the uppermost section of the retainer spring

24 ~ 25mm width at the top

I am pretty sure this was designed for the 'stubby' miniature 9 pin tubes, something like an 12AU/AX/AT series or 7 pin miniature tubes

COSMETIC CONDITION:

USED

Clean

Light oxidisation on the spring in some places, nothing serious though - pretty amazing after all these years!

Spring action is very "postive" meaning that it is not easy to alter the shape by force, it is not flimsy!

This retaining clip is now within a sealed clear plastic packet awaiting a "new life" in another piece of old gear ...