BACKGROUND:

Ex scientific equipment "pull", while I know the famous Penny & Giles name from the world of audio faders, this is a very special potentiometer built to high standards for industrial use.

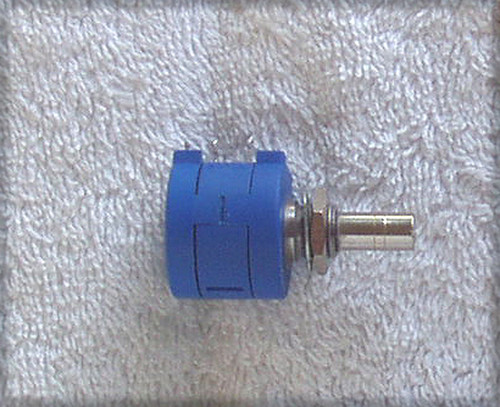

PENNY & GILES - Precision Potentiometer

Manufactured in UK

Part number: D20698/1

Rotary

Continuous rotation i.e no stop

It appears from information gleened at other websites, that the linearity should be 0.5% although Penny & Giles did produce pots with linearities of up to 0.05%

I cannot find any references to decode the part number of this pot so I am unable to confirm the standards it was built to, so I have assumed minimum (standard) ratings apply to this pot.

Repeatability would appear to be 0.01%

Rotational lifetime seems to be around 100 million at 10rpm running speed (that's a lot of turning - roughly 20 years of continuous operation!)

Nominally 4820 Ohm track resistance

A DETAILED LOOK AROUND ...

The potentiometer is fully enclosed, sealed. At the 'top end' of the pot (where the shaft exits the pot) there is a groove all the way around the body, this was originally used for mounting the pot. This groove is approximately 1.25mm wide.

The rear has the three terminals but these are special, being Gold plated very short, round terminal posts, half of which is insulated. In the original equipment, these posts had very small friction fit female plugs fitted to the posts - no soldering or crimping was used.

These terminal posts are 3mm in length x 0.9mm diameter

One post is offset from the other two, this is the wiper connection.

Top side is where the metal control shaft (looks to be stainless steel) exits the body, this shaft is 11.4mm length x 3.2mm diameter (round with no flat spot). The head of the shaft has an adjustment slot.

Around the Light Grey body of the pot is printed

PENNY & GILES CONDUCTIVE PLASTICS

BLACKWOOD GWENT UK

Handwritten is the part number

D20698/1

Serial No. 8829243

I think this is the first time I have seen a pot with it's own unique serial number! I would assume that this potentiometer was made to order and the manufacturer would have records of exactly which equipment the pot was installed in, presumably in case future servicing was required as each potentiometer replacement was probably a "special order" - this is supported by the very high prices for these pots, made to special order = $$$

Digging a little deeper now ...

Although I would have assumed a conductive plastic track was used for the pot, as it rotates there is a definite "click stop" tactile feeling as the shaft is rotated - this click feeling is not heavy but reminds me of a wirewound pot! Make no mistake, this "click position" feeling is very light but it is there.

I measured the total track resistance at 4820 Ohms.

I then made measurements while rotating the shaft using those little clicks as a guide, I found that with each 'click' the resistance changed by 100 Ohms and this was extremely repeatable i.e if I moved the wiper by 3 tiny "clicks" so that the resistance altered by 300 Ohms and then wound back the shaft by 3 clicks, the original resistance at that point had not changed at all, not even by a few Ohms. Of course the measured resistance changes smoothly over its travel (not in 100 Ohm 'bumps') but the very soft click position allowed for easy determination of how far the shaft had rotated for each resistance reading.

This pot was originally used as part of a position sensing system, servo feedback, so I guess that very high degree of resistance/position repeatability makes a lot of sense.

The shaft rotates continuously, there is no stopper.

Actual resistance readings indicated that the lowest resistance achievable was 30 Ohm and as rotation occured, this resistance slowly increased until after a full 360 degree rotation, the highest resistance is measured at 4820 Ohm. Continuing the rotation one more click and the reading drops to 'infinity' and then at the next click, the resistance cycle starts all over again, starting at 30 Ohm and increasing as rotation continues ...

As mentioned above, if I progressed rotating the shaft by a certain number of clicks forward or backwards and then returned to the original position, the measured resistance is identical to what it was before the movement - the resistance readings are highly repeatable.

DIMENSIONS:

Potentiometer body: 14.30mm height x 22.20mm diameter

WEIGHT:

10g

COSMETIC CONDITION:

USED

CLEAN

NO body or shaft damage

NO damage to the terminals

TESTING:

As outlined above, I have spent quite a bit of time making some measurements and sorting out the characteristics of this pot.

I did not observe any "funnies" i.e nice, smooth and even resistance changes with rotation of the shaft, no resistance 'flat spots' and once the shaft was non-moving, the resistance value was rock solid steady (no resistance drifting)

SPECIAL NOTE:

If you take a look around online for these precision pots, take a seat first!

These little critters are extremely expensive ($400 upwards when new) and the asking price even for used pots is very high.

I am not about to ask such high prices for a USED pot, no matter how good it may be, so I hope my price is considered far more realistic for a used precision potentiometer from Penny & Giles

I would believe anyone wanting this rotary potentiometer would be using it for development or experimental purposes, not servicing of existing equipment. For this reason I have tried to make the price realistic for such users.

I have now placed this rotary potentiometer onto a bed of foam and it is within a completely sealed clear plastic packaging awaiting a new owner!