Low cost commercial grade laser diode for R & D (much lower cost than a brand new component) custom projects, or educational use.

HISTORY:

Removed from secure fibre optic communications equipment used by the Federal Government, the equipment having been updated due to technological redundancy - prior to dismantling, the equipment was fully operational.

Optical communications has the advantages of extremely wide bandwidth and immunity from external influences such as EMI, RF and widely used in highly secure installations where it is not desirable to have "unauthorised" access to communications links.

Typical commercial uses are telecommunications, data networks and digital signal transmission

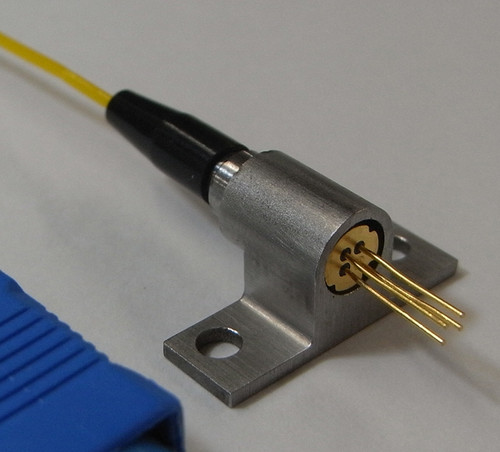

SUMITOMO - Optical Communications Laser Assembly

Coaxial package centred on the SLT4261-CS Laser Diode

Part number SLT4261-CS/RH1

Structure: InGaAsP/InP MQW-DFB laser diode module

Wavelength (centre): 1310nm

Power Output (Pf) is typically 2mW output, absolute maximum 3.5mW

Incorporates a single stage isolator

Flange type mounting, 12.7mm hole spacing - supplied with mounting hardware

Designed originally for use in long haul 2.5Gb/s fibre communication systems

Fiber tail is 80cm length

Terminated with a SC P BLUE connector

Supplied with a mating SC A BLUE panel mount socket, ready to create your own optical patch panel

3x plastic fiber clamps, used to route the excess fiber around the PCB (DO NOT CUT OR BEND THE FIBER AT SHARP ANGLES)

Pin designations are shown in one photograph, 4 pins (laser diode & PD)

I have included a basic block diagram of a typical laser diode communications (transmitter) design, "something to give the users an idea" - you can start with a very basic design (and it's inherent limitations) or design an extremely sophisticated "fail safe" laser communications module based on this Fujitsu laser device

Included in the package is a "monitor photodiode" which receives emission power from the rear facet of the laser diode and can be used to control the optical power coupled into the fiber.

COSMETIC CONDITION:

EXTREMELY carefully removed from equipment (ESD precautions and also stored in ESD bags)

Fiber cable has been handled with care, no sharp bends and certainly no "kinks"

Leads to the diode assembly are clean and ready for re-soldering

NOTE: These leads were soldered to the original equipment boards "flat" onto pads not through hole, this is how they are designed to be mounted, not "through hole" as is common with more common with semiconductors.

TESTING:

Removed (eventually - we had to wait for special clearance before making the "cutover" to the new equipment as maintaining of communication system integrity was critical for the client) These devices and the rack modules they were installed in were absolutely fully functioning prior to removal.

I have NOT re-tested them since removal though.

See the photograph showing the laser diode packed in a hard plastic case - this is how they will be received, not loose!