Low cost commercial grade laser diode for R & D (much lower cost than a brand new component) custom projects, or educational use.

Optical communications is the way forward, extremely wide bandwidth and immunity from external influences such as EMI, RF and widely used in highly secure installations where it is not desirable to have "unauthorised" access to communications links.

Typical commercial uses are telecommunications, data networks and digital signal transmission

This optical device was removed from secure law enforcement communications systems (upgrade) but are not just limited to that purpose.

I have included a basic block diagram of a typical laser diode communications (transmitter) design, "something to give the users an idea" - you can start with a very basic design (and it's inherent limitations) or design an extremely sophisticated "fail safe" laser communications module based on this Fujitsu laser device

Included in the package is a photo diode and this monitor photodiode receives emission power from the rear facet of the laser diode and can be used to control the optical power coupled into the fiber.

This device is the basis for an optical communications transmitter, I also have 1330nm receivers/diodes for use as receivers listed separately.

Here are some of the technical details ...

Fujitsu Laser Diode (with PD)

Model: FLD3C5LK

Structure: InGaAsP/lnP MQW (Multi Quantum Well)

Wavelength (centre) 1300nm

Bandwidth typically 1.5nm (that's around 250GHz)

Pf typically 0.2mW (Iop 15mA, VF 1.2V)

I have a large amount of information about the device characteristics, see a couple of my screen shots for examples but I can supply this information (and much more) directly to you, if requested.

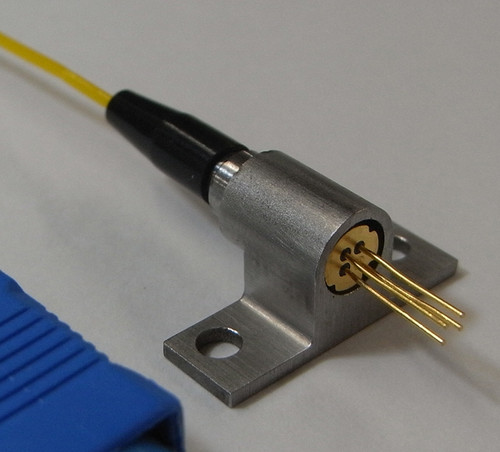

I have also included a photograph of the pin designations, comes in handy to know what each pin does!

Fiber tail is 1.2m length

SC P (SSC P) BLUE Suhner connector

Supplied with a mating SC A (Suhner) panel mount socket, ready to create your own optical patch panel

4x small plastic fiber clamps, used to route the excess fiber around the PCB (DO NOT CUT OR BEND SHARPLY)

COSMETIC CONDITION:

EXTREMELY carefully removed from equipment (ESD safety observed)

Fiber cable has been handled with care, no sharp bends and certainly no "kinks"

Leads to the diode assembly are clean and ready for re-soldering

NOTE: These leads were soldered to the original equipment boards "flat" onto pads not through hole, this is how they are designed to be mounted, not "through hole" like a transistor

TESTING:

Removed (eventually - we had to wait for special clearance before making the "cutover" to the new equipment as maintaining of communication system integrity was critical for the client) These devices and the rack modules they were installed in were absolutely fully functioning prior to removal.

I have NOT re-tested them since removal though.

Stored in a special container to ensure the safety of the fibre cable especially.