HISTORY:

Imported from an international research laboratory (by ship!) as the equipment was being disposed of due to the previous establishment upgrading their equipment in the early 2000's. This is yet another very nice item of industrial equipment which I have decided will become an organ donor.

It is the MATSUNAGA (Yokohama Japan) Frequency Converter, intended for laboratory use and providing up to 240V AC at a user adjustable variable frequency. Not only that, the AC voltage output could be varied across a wide range AND the user could set current limiting, so it could alter all three aspects of the AC output wavefrom, frequency, voltage and current limiting. I actually fired this gear up and it was working great but oh dear! What to do with it? Sure you could put up on the workbench but at that sort of weight it needed a lot of space and a good solid workbench. I decided a while back to offer this equipment as a complete unit "elsewhere" online for a while but there was no interest at all so I pondered over what to do with this equipment (to keep or not to keep) but it had a few things going against it.

As a complete unit it was EXTREMELY HEAVY, over 50Kg, which means that my arms are now 30cm longer from lugging this beast around the workshops! ... but more seriously, shipping would have been difficult to ensure safe travel AND very expensive. It also had other minor cosmetic issues because it is not easy moving such a monster around so it suffered scrap marks on various places of the all steel casing.

So, the "donor operation" has begun and here is the main transformer used in the frequency converter, high current capable, STEP UP and designed to function effectively across a wide frequency range, right up to 1Khz.

Keep in mind that most of the AC "wound" components (chokes, current transformers, AC step up or down transformers for example) were designed for use across a wide FREQUENCY range, not just the usual 50 ~ 60Hz as the equipment allowed the user to change the line frequency from 40Hz right up to 1Khz

ALL output from the equipment went via this transformer.

The component manufacturer, Haruna-Denki (Tokyo Japan) began operations in 1981 and remain active in the design & manufacture of generator sets, transformers, high power equipment etc

HARUNA-DENKI (Japan) - AC Power Transformer

Made in Japan

Manufactured 1996

Step Up design

Physical: E core laminated

Type #: PT-20405A

The transformer ID convention used by the manufacturer is that the secondary ALWAYS has the current rating indicated, the primary only has the source voltage, without a current indication.

Keep in mind that this transformer can be used in either direction but take into account that the current rating does not change and the likelihood of higher turn on "in-rush" currents if used in "reverse", especially in a transformer of this size!

Primary AC Voltage: 0V - 5V - 80V - 90V

Secondary Voltages:

2x 0V - 125V

1x 0V - 50V

0V-125V current rating: 3.5 AMP per winding

0V - 50V current rating: 200mA

That is around 885VA !

ALL windings are completely isolated from each other, this is NOT an auto-transformer design.

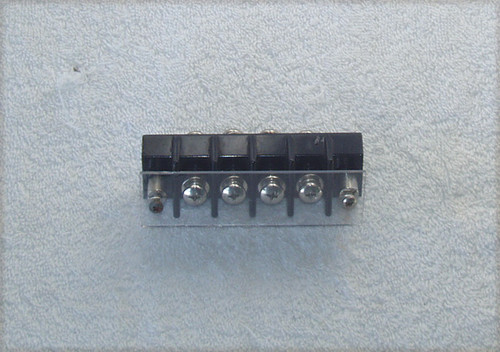

The primary windings all have screw terminals

The secondary windings are solder tags

Printed on the outer plastic insulation is the clearly marked winding designations and the part # PT-20405A with the year and perhaps month code of manufacture plus the manufacturers name, HARUNA-DENKI (Japan)

Designed for use across the frequency range of 40Hz ~ 1000Hz

Frame has 4x slot fit mounting feet, no mounting screws/bolts supplied

DIMENSIONS:

135mm height x 154mm width x 150mm depth

The base mounting feet are included in the above depth measurement

Weight: 12Kg

COSMETIC CONDITION:

USED (but as new)

NO damage to the laminations or frame

NO damage to the side mounted solder tags nor the screw terminals

TESTING:

The user of this transformer absolutely MUST know what they are doing and be familiar with transformer theory, operation and safety precautions.

This transformer can create not only high voltages but the currents are enormous!

TAKE GREAT CARE! (for your safety)

This is what really matters, how does it perform?

Prior to equipment dismantling, this equipment was functioning just fine (see above) but I wanted to take a closer look at this transformer and the possibilies it offered.

First up, a DC resistance test to make sure all windings are ok (since de-soldering) and isolated between each other and a megger test to frame showed infinity. Definitely each winding is isolated from any other winding.

Let's kick this transformer into life and make some voltage measurements ....

I tested this transformer using my trusty high powered GRUNDIG Variac, first with the lowest AC voltage I can wind the variac down to, 60V AC. The measured secondary output on each 125V winding was 87V AC and the 50V winding, 34V - all good. I then wound up the source voltage to the primary to the normal 90V and measured 130V AC NO LOAD on each winding. I also checked the 50V winding and this measured 53V AC NO LOAD.

Often with such a high current transformer I would hear a buzz immediately upon turn on, the initial current surge but I noticed there was no buzz at all and the variac current meter did not "flick" as it would if a surge had occurred - nice!

NO surprises in operation, looking great!