HISTORY:

Sustainability is the name of the game! Anything (that has been tested and still functioning properly) should be repurposed creating saving in wasted Ee and reducing the poisoning our environment when items are buried in the earth at the local tip needlessly.

Never heard of Ee? It is a concept that creates a measurement of ALL things (not just electronics) that humans have made and the energy used in obtaining the raw material, processing the materials right through to a finished product and even should include the shipping of the item to the distributors/retailers.

If you would like to know more about Ee values, please take a look HERE

While the Marantz PMD340 is a good workhorse in the audio production environment, it becomes pretty useless once the CD drive fails and the laser assembly has gone A.W.O.L!

This machine was in use by us for long periods in a studio environment, never missing a beat until the laser needed replacing. Tech's took the laser electronics out to have them replaced and "poof" disappeared, somewhere. So I have this PMD340 which is absolutely fully functional but without a laser - pretty useless.

I no longer am prepared to spend time servicing our equipment (retired and TRYING to have a break from all that) and as a result, this equipment has now become an "organ donor" for other PMD340 owners.

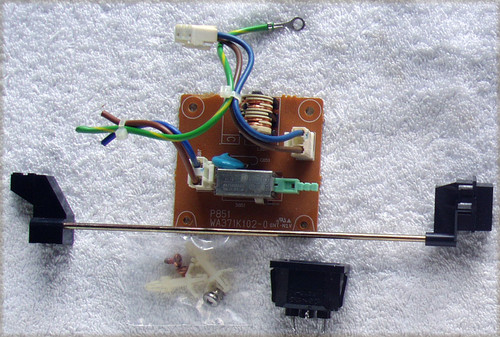

This is the CD MECHANISM, which is referred to in the Service Manual as the CDM assembly

SPECIAL NOTE: This CDM is ONLY offered for parts, not as a complete working unit (otherwise I wouldn't have "operated" on the PMD340 would I?)

The laser is present, in fact everything is still intact EXCEPT the sub-board called SERVO PCB (P101) - that board is vital for the system to control the CD servo's and processing of the data from the laser head. In the process of servicing this PMD340 (it had CD reading issues), the servo board was removed and LOST! So there will no Servo board supplied at all.

BUT "she" (the CDM) still can be a useful organ donor, that tray front panel with the CD TEXT decal, the tray motor, laser positioning motor and spindle motors, the nylon tracks, leaf limit switches and perhaps even the laser head assembly (looks to be a LTOH30PA 3 beam laser head, it's hard to read!) jump to mind. If someone wanted just the tray motor for example, I can extract it to reduce the shipping costs (the whole mechanism weighs 500g)

Perhaps you need a different part for your PMD340 ... To see the other items I have from our PMD340, please take a look HERE

MARANTZ - CD Player CD MECHANISM ONLY

General Information PMD340

Made in Japan

Rack case construction

Single CD unit

Supports standard CD-DA discs but ALSO CD-TEXT (extremely useful for production house produced CD's which may have special information in this area)

Large easy to read Orange backlit display

Pitch change/bend user control

Analog audio outputs (Balanced & Unbalanced)

Digital outputs (SPDIF)

Error correction method: Cross-interleave Read Solomon code (CIRC)

16 bit linear quantization

Built in test modes (explained in the Service manual)

Wired remote control ports

Now to the specific information about this PMD340 Module, the CD MECHANISM

Part # various part numbers, overall this is referred to as the CDM

This is where it all begins, everything else in the PMD340 waits for instructions from or to be sent to this mechanism. Demonstrated by the fact that we had a PMD340 still "working" with respect to the front controls etc but of course, no CD information being sent to the main board.

Simple to "drop in" as a replacement (no soldering required) but quite frankly, I see the value in this mechanism is those parts which would be so hard to come by (as mentioned above)

NO permanent interconnections, all signals are routed via connectors on this module

Practically all plastic construction

Screw down supports using those famous Copper coloured screws (which are fake copper, as they are in fact ferrous) - I will supply ALL the screws used to secure this mechanism within the case.

CD MECHANISM DIMENSIONS:

180mm deep x 130mm wide x 55mm height

TESTING:

Prior to the equipment failure (read errors) all was well with the world. The tech's determined the laser head had done it's dash and needed changing and that is when things went "pear-shaped" - the Servo board went "astray" and this was also about the time I was closing down our business anyway, so things were just a bit chaotic (actually they still are!)

So the CDM was working, but of course is no longer - she won't do anything without that Servo board fitted!

TRIVIA!

The spindle motor rotates at TWICE the "normal" speed to facilitate functions such as "INSTANT PLAY" - another bit of useless information!

I have now placed this mechanism onto a bed of stiff cardboard/bubblewrap and completely sealed in clear plastic. I can either send as the complete unit or (for the buyers convenience) remove specific items from the CDM e.g motors etc and repackage them for safe shipping.