As removed from a lovely Champagne Marantz Stereo Amplifier Model: PM 310

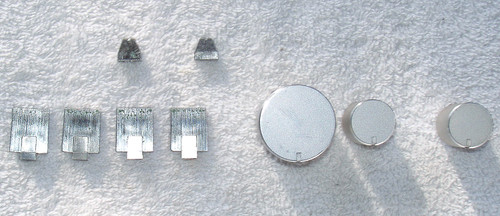

These are all of the front panel potentiometers, 2x slide/fader pots and 2x rotary pots

These are pretty specialised pots, especially the rotary type - please read my details below

Offered as spare parts for the PM 310 OR possibly other Marantz or non-Marantz equipment. I have provided some detail that may help decide if these could be used in other equipment.

Marantz Stereo Amplifier SPARE PART ONLY

Model: PM 310

Marantz part # various

Potentiometers

2x slider pots MOUNTED on a PCB (PE00/K207H1650) 50K C curve each

1x rotary pot 200K B curve

1x dual rotary pot 100K B curve

The rotary pots are NOT your ordinary "3 leg" variety, see below about this

ORIGINAL FUNCTION: BALANCE CONTROL

Alps Japan

Part # RK02040110

1/4" fluted shaft 23mm

Body diameter: 15mm

PCB mounting

200K rotary pot (B curve) with a centre tap

Pot rotation is physically indented in the middle of travel (at the centre point, the shaft drops into a small recess which does not lock rotation but provides positive tactile feedback to the user that this centre point has been reached e.g balance between two audio signals, left and right.

Think of this as a normal pot with a fixed resistance track but with a centre tap provided. The wiper then runs the full length of this fixed resistance track. You end up with a variable resistor which has 3 (not the normal 2) points at which the resistance between the wiper and the fixed track is zero (or close to it).

This is why the pot has 4 connection points, not the normal 3.

I actually made a few resistance tests to see this in action, the actual readings I obtained were:

Full fixed track resistance 179K Ohm

Centre tap point resistance 89K Ohm

As the wiper is moved from one end of the fixed track to the other end, the resistance changes smoothly (no flat spots)

Based on my "real life" measurements, this pot has a value tolerance of around 10% (actual indicated resistance is 200K)

ORIGINAL FUNCTION: VOLUME CONTROL

Alps Japan

Part # RM01040400

1/4" fluted shaft 23mm

Body diameter

100K dual rotary pot (B curve) with centre taps (4 connection points)

As the shaft is rotated, there is tactile feedback in the form a soft but definite indents. This allows for a positive feel as the pot is rotated and corresponds with the multitude of dB points indicated on the front panel Volume scale - there are actually 40 small indents as the pot is rotated. This indenting is achieved by a special mechanical arrangement at the rear of the pot.

I made real time resistance tests of this dual pot and the results were:

Front pot

Full fixed track resistance 83K Ohm

Centre tap point resistance 44K Ohm

Rear pot

Full fixed track resistance 81K Ohm

Centre tap point resistance 43K Ohm

As the wiper is moved from one end of the fixed track to the other end, again the resistance variation occurs smoothly and without any flat or dead spots

This dual pot appears to be slightly out of spec if it is supposed to be a 10% tolerance pot as the lowest track resistance should be around 90K Ohm, but my assumption of a 10% tolerance could also be incorrect!

DUAL SLIDER POTS: TREBLE & BASS CONTROL

These are mounted on the PE00 board, also populated with passive components - there are no semiconductors on this board.

The original flying leads remain intact and were desoldered from the main board (or removed from the wire-wrap post)

NOTE: Construction techniques used at the time mean't that a lot of connections were wire wrap. Some of the flying leads are solid core wire wrap but can still be soldered instead of installing using wire wrap techniques (you can still get wire wrap tools from the likes of Element 14)

I have now safely sealed all of these components in plastic to maintain their present condition and keep out dust/dirt.