HISTORY:

Oh my! Today, while working through yet more reel to reel related spare parts, I have found some of our old R2R tape machine spare parts. Most of the parts are 'mundane' i.e not exciting items such as head assemblies, VU meters or the motors (they all found new machines to live in yonks ago) but some of these less interesting components that I will be listing could be of benefit to others who have the specific machines 'lying around' waiting for a spare part (or two or three ...)

I am very much "into" sustainability and a complete tape machine represents a LOT of embedded energy and to waste that embedded energy is a very bad thing, even worse is to bury it in landfill and subsequently poison our environment!

What is embedded energy?

Embedded energy is a measurement of the total energy that was used to create a component, a module or a complete piece of equipment originally.

HERE is some more information about Ee

So my motivation is 'saving things' where they may be old but still useful or possibly be repurposed.

Back to this component I am offering ...

Go back in time, in the 1990's our Australian Broadcasting Corporation was 'forced' by Federal Government funding decisions to 'clear out the cupboards' of their old, obsolete equipment.

Masses of fantastic high quality equipment used in the broadcast industry suddenly became available in the Australian market place through auction houses such as Pickles.

Masses and masses of gear of all types and what's even better, there was often a friendly ABC engineer on hand who could answer techie questions about the gear being offered. Not only that, much of the equipment had original full Service manuals - to me this was like 'techie heaven!"

Although it was hard to constrain ourselves, the bidding was stupidly low and many took advantage of getting great gear for "a song"

I am not a trader in such things but I ran an audio post production facility for many years and we worked with client's source material using 1/4", 1" and 2" tape formats so just imagine my glee when I saw this array of OTARI's and STUDER's being offered (by the truckload and with all the trimmings such as the aluminium reels and original Studer NAB hubs - Wow!)

I bought a LOT of those machines in all the different tape formats and produced my 'dream machines' by taking parts that needed servicing from other machines - ending up with some "perfect" OTARI's and more importantly STUDER 810 & 820's!

In my opinion, the STUDER is a superior machine but the OTARI is good too, and it was originally a cheaper machine to purchase.

Any excess STUDER gear went overseas back to Germany (they were scrambling for the spare parts) and also the OTARI 'leftovers' went the same way but locally HOWEVER today I have found a few more bits and pieces from the OTARI MX5050 BII specifically.

Please don't ask if I have a complete, working machine - I don't because all the "good stuff" left home quite some time ago - now there are just a few parts that I am hoping someone can make use of ...

If this component from the MX5050 BII/III machine isn't what you are looking for ... try searching HERE to see the other components that may still be available

Here are the details of this spare part from an OTARI BII (competed against the STUDER B67)

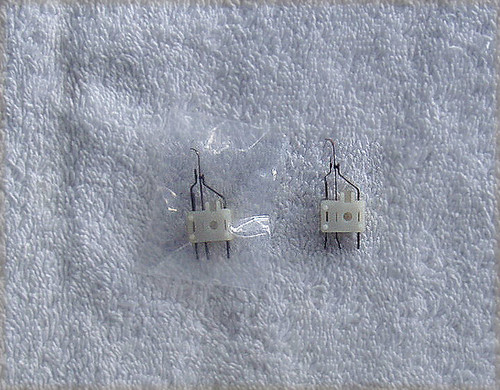

OTARI (Japan) - Panel Switch Assembly With Button & Mounting Hardware

Parts offered (as pictured) are: the DPDT locking push switch, Yellow rectangular knob, felt dust screen, U shaped metal mounting bracket

SPARE PARTS ONLY

Extracted from the MX5050 BII

If you are working on this machine I expect you will have the full Service Manual (if not, I do see a number of sites offering these for no cost but make sure you get the correct suffix of machine)

This switch is located directly below the Output Level concentric control on the Right Hand side of the deck front panel (lower section)

The Service manual refers to these as SW101/SW202 - I have only found one of these assemblies so far. The actual switch is an ALPS (Japan) type A609

The function of the switch is to allow monitoring of either the signal source to the machine or the output off the tape, the switch contacts are handling "live" low level analog audio signals.

TESTING:

I have checked the electrical operation of the switch, no issues at all. I noticed two small holes in the top of the switch which give spray access inside, so I gave it a "squirt" to make sure the wipers are nice and clean.

COSMETIC CONDITION:

USED

CLEAN

NO damage to any component being offered i.e switch is in great condition, bracket is not bent and the Yellow LONG rectangular knob is unmarked, not discoloured and remains a nice "Mustard Yellow"

Switch action checked, nice smooth travel and the locking works correctly!

I have now placed this complete switch assembly into a sealed clear plastic packet while it waits it's destiny with another MX5050 machine